supply chain solution footies Baby Romper company

1

Streamlining Supply Chain Solutions for Baby Romper Manufacturers

The global market for baby and toddler apparel presents a promising opportunity for manufacturers who can deliver premium-quality products with efficient turnaround times. For factories specializing in baby rompers, the dynamic demands of modern buyers require seamless supply chain management to achieve scalability and reliability. By incorporating effective strategies, this factory can navigate production challenges and secure a competitive edge.

Optimizing Raw Material Procurement Processes

One critical aspect of supply chain solutions for this factory involves sourcing top-grade materials designed for the sensitive skin of infants. Bamboo-based fabrics, for instance, have become increasingly popular within baby apparel. Our facility ensures that suppliers provide pre-tested, certified bamboo textiles suitable for crafting bamboo baby pajamas, footies, or rompers. Partnering with credible vendors minimizes risks in receiving substandard materials, while long-term contracts with suppliers help to stabilize pricing.

Another essential consideration is material diversification for expanded product offerings. Examples include plush fabrics ideal for a blanket for kids or stretchy organic cotton blends for kids clothing girls. By maintaining a well-organized database of material specifications, delivery lead times, and costs, this factory significantly reduces wastage and enhances production scheduling.

Integrated Manufacturing Systems to Respond to Variable Demand

Supply chain alignment starts with aligning the assembly process to meet varying levels of demand. This is particularly crucial in producing seasonal items like bamboo baby pajamas or rts bamboo pajamaskids clothing girlsgirls clothing sets. During peak shopping seasons, delays in fulfilling bulk orders can result in loss of revenue and partner dissatisfaction. To circumvent this issue, this factory leverages advanced production planning software and centralized data systems to allocate resources appropriately.

For instance, our facility categorizes product lines by demand forecast and adjusts machinery schedules to prioritize fast-moving goods, such as baby rompers and footies. Consistent collaboration with freight providers ensures that shipments of finished goods avoid delays due to congested shipping ports or customs bottlenecks.

Ensuring Consistent Product Quality Through Quality Management

Infant clothing requires stringent adherence to safety and quality guidelines to meet global and local compliance standards. This factory adheres to systematic quality control processes at every stage of manufacturing. From fabric inspection before cutting to final packaging, multi-tier quality checks ensure customer satisfaction and retention.

Given the rising demand for sustainable kids clothing, integrating certifications that validate the eco-friendliness of products can act as a value proposition. As such, third-party verifications for bamboo fiber integrity or formalized audits may be applied to products like bamboo baby pajamas and girls clothing sets. This practice not only reduces returns but also builds strong B2B client trust.

Custom Design and Rapid Prototyping

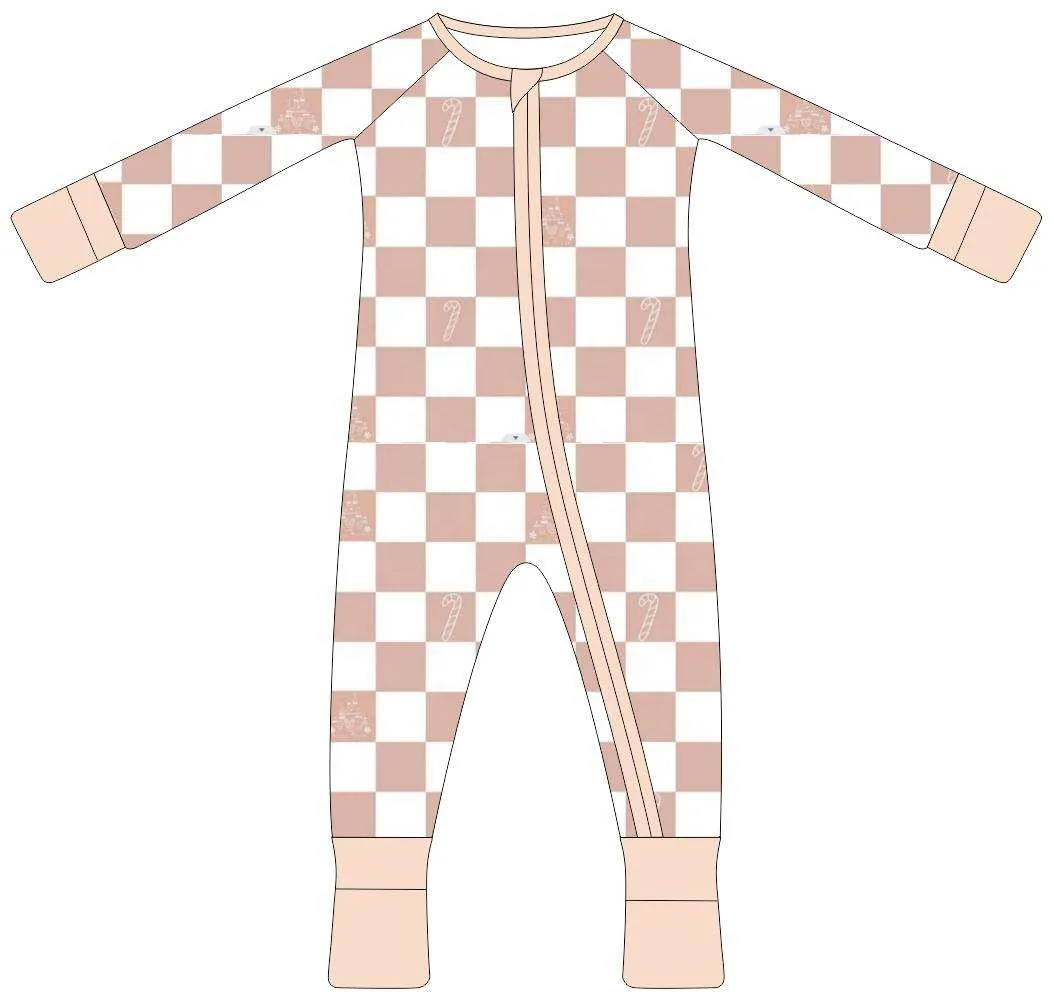

In the highly competitive baby apparel market, flexibility to cater to bespoke customer requirements is often a decisive factor. By incorporating CAD-driven design systems, our facility can accommodate intricate client specifications for childrenswear, such as custom prints for rompers or theme-based patterns on a blanket for kids. This dedication to meeting client design requirements has enabled faster go-to-market strategies, helping retailers keep pace with consumer preferences.

, employing rapid prototyping techniques shortens the product development cycle. For example, new patterns for kids clothing girls can be iteratively tested and approved without stalling production schedules for other items.

Warehouse Organization and Inventory Management

Efficient warehouse management contributes significantly to streamlining the entire supply chain. This factory utilizes an automated inventory system to monitor raw materials, work-in-progress stocks, and finished products. Whether for seasonal goods like rts bamboo pajamaskids clothing or all-year-round baby rompers, real-time updates ensure that supply shortages do not disrupt production pipelines.

To further optimize storage logistics, lightweight products like bamboo baby pajamas are often stored separately for quick retrieval. Bulkier goods, such as blankets for kids, are assigned dedicated areas to ensure efficient packaging and dispatch without delays. This strategic organization reduces lead times, improves space utilization, and mitigates redundancy in operations.

Collaborative Logistics and Distribution Strategies

Transportation efficiencies are critical when delivering orders globally or regionally. This factory builds strong partnerships with logistics providers to ensure timely delivery of orders. Multi-modal shipping options are often employed to reduce transit times for international shipments without significantly increasing costs.

Additionally, this factory employs drop-shipping models for certain clients seeking reduced lead times and cost-effective solutions. This system enables retail partners working with products such as kids clothing girls or girls clothing sets to operate more efficiently by shifting inventory management responsibilities toward the manufacturer. Strategic collaboration with freight forwarders also minimizes disruptions caused by ever-changing geopolitical or regulatory constraints.

Leveraging Technology for Transparency and Communication

Ensuring seamless communication across the supply chain remains vital. Technology integration, such as enterprise resource planning (ERP) platforms and customer relationship management (CRM) tools, assists this factory in consolidating all operational metrics into a unified system.

This degree of transparency allows B2B clients to track the progress of their orders in real-time, whether for bamboo baby pajamas or seasonal girls clothing sets. , proactive reporting systems communicate any possible delays or inconsistencies at any stage of production. These platforms reinforce mutual accountability between the manufacturer and its partners.

Eco-Friendly Commitments Driving Industry-Leading Operations

As consumer awareness of sustainable apparel rises, businesses must align their values with eco-responsibility to remain relevant. Our facility has implemented various green initiatives, such as energy-efficient production systems and waste reduction protocols, to cater to the increasing demand for environmentally friendly products.

The focus on materials like bamboo provides a dual advantage: it aligns with sustainability benchmarks and appeals to retailers targeting eco-conscious consumers. Bamboo’s fast-growing, renewable properties make it exemplary for products like bamboo baby pajamas and rts bamboo pajamaskids clothing, offering environmental benefits while maintaining product durability.

Building Long-Term Partnerships with Retailers

This factory recognizes that building strong partnerships with retailers strengthens its supply chain reliability. By providing constant updates around key metrics—such as lead times, delivery schedules, and order customizations—our facility fosters trust-building opportunities with B2B buyers.

, presenting add-on services such as pre-branded packaging, marketing support for flagship items like footies, and transparent MOQs (Minimum Order Quantities) further differentiate this factory’s value in the competitive marketplace for baby rompers and accessories.

Scalability through Continuous Improvement

Adaptability remains a core principle in securing long-term supply chain success. This factory conducts periodic evaluations and performance audits of its suppliers, warehousing channels, and logistics operations to identify areas for cost optimization and scalability. Data insights from previous orders, particularly high-demand items like kids clothing girls, are utilized to refine supply chain strategies for diverse market needs.

Additionally, introducing modular workstations and retraining manufacturing staff ensures faster responses to upscaling production, which is essential for managing the high-volume demands of retailers specializing in girls clothing sets or seasonal bamboo baby pajamas collections.

Transforming the Supply Chain for Future Growth

The evolving priorities of modern B2B buyers drive the need for a refined approach to supply chain management. Streamlining processes such as material procurement, production scheduling, and logistics coordination has enabled this factory to meet market demands efficiently. Through constant innovation, sustainable practices, and technological integration, this facility is poised to address the challenges and needs of an ever-changing industry while ensuring its partners receive the highest value.