professional kids bamboo pajamas character wholesaler organic service

1

Professional Kids Bamboo Pajamas: A Wholesaler’s Organic Service Expertise

In the competitive world of B2B trade, factories specializing in bamboo-based kids' pajamas have become synonymous with innovation, eco-responsibility, and service reliability. Retailers and resellers, looking to establish impactful relationships with suppliers, often prioritize partners who offer more than just products, focusing on features like sustainable materials, customized production, and seamless buying experiences. This factory specializes in professional-grade kids' bamboo pajamas, backed by a strong emphasis on organic manufacturing and dependable wholesaling services.

Bamboo Fabric: The Foundation of Sustainable Kids’ Pajamas

Bamboo has emerged as a preferred material across the textile industry due to its exceptional softness, antibacterial benefits, and sustainability profile. Kids’ pajamas made from bamboo are celebrated for their breathability, making them a perfect choice for sensitive and growing skin. Our facility employs advanced fabrication processes to produce bamboo pajamas that meet rigorous environmental and health standards while adhering to high levels of fabric purity.

An added benefit of bamboo fabric is its moisture-wicking ability. The pajamas crafted at this factory keep children comfortable and cool throughout the night, no matter the climate. These qualities have attracted businesses that value not only functionality but also the wellness-oriented lifestyle associated with bamboo products, making this material ideal for crafting professional-grade kids’ sleepwear.

Customization for Retail Brands: From Design to Delivery

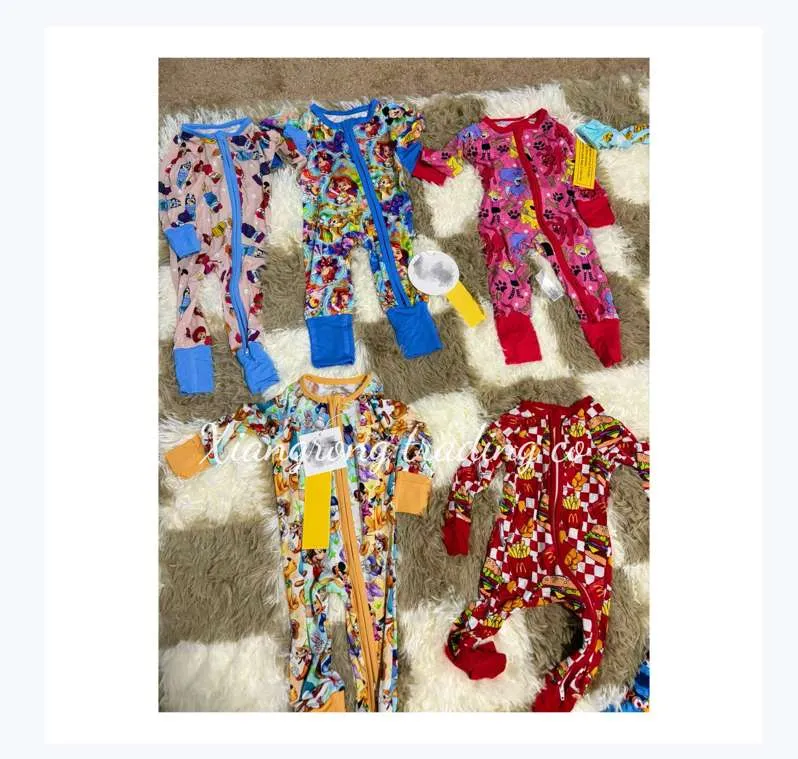

One of the standout offerings in the professional kids' bamboo pajamas sector is customization. Our factory partners with brands to create unique, appealing designs that capture customers’ interest. From innovative prints to tailored fits, personalized production is a core part of the service.

For instance, the facility specializes in making printed baby clothes that combine branding elements with aesthetic charm. Retailers can specify design themes, color palettes, patterned adornments, or even original graphics to suit their market demands. With advanced printing technology and attention to detail, the results brand visibility while staying true to high-quality bamboo standards.

Scalable production flexibility is available for every client. Whether a small business requires a low MOQ bamboo blanket to test market demand or larger enterprises need consistent bulk supplies, the factory adapts to the client’s unique volume requirements without jeopardizing product integrity or lead time commitments.

Organic Certification and Material Focus

Moving beyond basic manufacturing, this facility ensures all bamboo fabrics used in kids’ pajamas are certified organic. This emphasis on ethical sourcing assures clients that the entire production line—from raw cellulose extraction to finished garments—is environmentally conscious and free from harmful chemicals. Dedicated quality checks during every stage validate the organic status and uphold regulatory compliance.

Efficiency Without Compromise on Quality

Efficiency in production timelines is another hallmark of this factory’s professional service. Operating systems are designed to streamline workflows, allowing retailers and wholesalers to rely on predictable timelines without compromising on quality standards. Time, after all, is a crucial metric in the B2B world.

Our internal production facility focuses on optimizing operations to ensure consistent fabric dye quality, stitching precision, and finished product durability. This careful orchestration of production resources has reinforced relationships with a diverse base of partners, from boutique brands to global distributors.

Packaging and Delivery Tailored for Wholesale Buyers

Along with impeccable production reliability, thoughtful packaging and shipping are critical to the services provided. Each shipment is prepared with care to maintain the integrity of bamboo fabric and prevent damage during transit. Custom labeling and packaging options are available for brands looking to create an elevated unboxing experience for their customers.

Wholesalers appreciate the transparency during the logistics processes, with real-time monitoring, accessible tracking updates, and clear communication channels ensuring seamless delivery. For clients dealing with multiple SKUs, efficient sorting and tracked packaging save both time and effort.

Women Bamboo Viscose Pajama Set Manufacturing

As part of its diverse product portfolio, this factory also caters to adjacent markets, such as women’s loungewear. The women bamboo viscose pajama set exemplifies how eco-focused materials can combine refinement and comfort. Viscose, derived from bamboo fibers, feels luxuriously smooth upon touch while retaining its sustainable attributes.

The pajama sets for women are engineered to be both stylish and functional. Multiple style options, including button-down tops, relaxed-fit pants, or even coordinated shorts, match varied retailer preferences. Each set is crafted with an equal focus on practicality and sophistication, ensuring wearers experience maximum comfort without compromising elegance.

Batch Sizes and Customization for Differentiated Markets

Clients catering to females aged 20 to 40 often leverage smaller batch sizes or unique seasonal designs to stand out in their markets. In these cases, our facility collaborates closely with brand owners from concept design through to the final product. Offering guidance on bamboo fabric textures, color trending, and pajama set patterns, collaborations result in highly differentiated collections that draw attention in competitive retail spaces.

By covering kids’ and adult apparel categories, the facility serves as a holistic solution for brand portfolios targeting diverse customer segments. Such a broad yet specialized product offering simplifies supply chain challenges, allowing companies to scale operations without relying on multiple vendors.

Simplifying Low MOQ Requests with Scalable Solutions

An ongoing challenge for many resellers, particularly new players in the market, is meeting the supplier’s minimum order quantities. The facility supports low MOQ bamboo blanket manufacturing, opening the wholesale market to smaller enterprises that want to test niche product lines. Our processes accommodate pilots or limited-scale runs while guaranteeing the same level of quality delivered to larger partnerships.

Simplifying smaller purchasing allows boutique businesses to experiment with market opportunities before committing to full-scale launches. Additionally, emerging brands seeking unique offerings, like ultra-soft bamboo blankets, benefit from this streamlined service model. Strategic attention is given to ensure ease across all phases—from prototyping to swift production execution.

Technological Advancements in Organic Sleepwear Manufacturing

Modern production facilities are increasingly investing in technology to deliver high efficiency and consistency. This factory integrates cutting-edge machinery to process bamboo fibers, weave exceptional-grade fabrics, and implement advanced stitching methods. Automation tools are used to eliminate errors in processes such as dyeing and pattern cutting. Yet, the operation retains essential human quality control inspections to ensure perfection throughout.

Technology aids in reducing waste, preserving resources, and improving operational timing—all while maintaining a strong commitment to organic practices.

Client-Centric Approach for B2B Success

In the B2B space, service is as important as the product itself. Our team prioritizes long-term collaborations, ensuring transparent communication at every stage of the buying cycle. From initial inquiries about sourcing kids’ bamboo pajamas to receiving bulk deliveries, retail clients feel supported and informed throughout.

A dedicated account management team responds swiftly to questions, addresses concerns, and provides critical information, such as production timelines, bulk customization options, and ongoing trends within the bamboo apparel sector. Clients repeatedly emphasize how crucial this sense of partnership has been to their operational success.

Eco-Responsibility: Building a Future with Sustainable Choices

This facility recognizes its role within the global supply chain and understands the importance of eco-friendly manufacturing. Reducing the carbon footprint while maintaining industry-leading quality is not just a goal but a standard. Solar-powered operations, water-conserving dye processes, and responsible sourcing of bamboo ensure the sustainability ethos of these products is carried through each production phase.

Partnering with the factory allows businesses to not only align with their sustainability goals but also appeal to environmentally conscious consumers who are increasingly making mindful purchasing decisions. Organic products such as kids’ sleepwear, low MOQ bamboo blankets, and women bamboo viscose pajama sets demonstrate daily-use items can balance comfort, affordability, and responsibility.

Shaping the Future of Bamboo-Based Sleepwear Trade

For buyers navigating the B2B marketplace in search of reliable, sustainable, and professional suppliers, this factory stands out as a leader in producing organic kids' bamboo pajamas and related products. With its seamless integration of low MOQ options, efficient production, customization services, and commitment to ethical practices, it offers businesses an avenue to build resilient retail operations in tune with contemporary consumer demands.

Whether through crafted printed baby clothes that charm parents or elegant bamboo viscose pajama sets designed for women, this facility combines technical expertise with sustainable business values. Excelling in wholesaling operations, the focus remains on creating products that illustrate the perfect synergy between function, ecology, and commercial appeal.