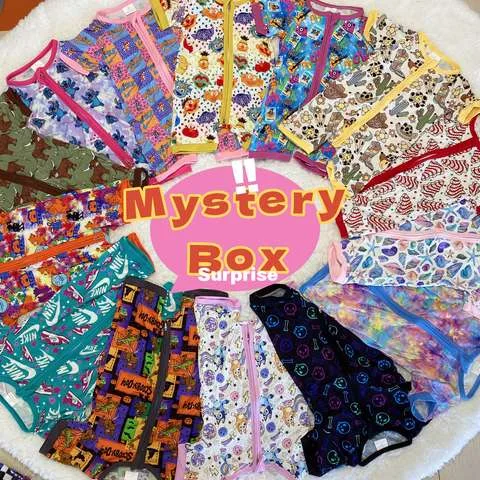

Private Label Custom Print Bamboo Pajamas Astm F963 Supplier

Overview of Custom Print Bamboo Pajamas

Custom print bamboo pajamas are revolutionizing the world of sleepwear by combining eco-friendly materials with personalized designs. Bamboo fabric is celebrated for its sustainability, breathability, and comfort, making it an excellent choice for sleepwear. However, bringing custom designs to life on bamboo pajamas requires technical precision in fabric selection, density measurement, and industrial machinery configurations.

The Role of GSM in Bamboo Fabric for Pajamas

Grams per square meter (GSM) is a key metric in fabric manufacturing that determines the weight and thickness of the material. Bamboo fabric typically has GSM values ranging from 150 to 300, depending on the application. For pajamas, achieving the perfect GSM balance is crucial to ensure comfort, durability, and breathability.

In the context of custom print bamboo pajamas, GSM plays a pivotal role. Lower GSM values (around 150-180 GSM) result in lighter, more breathable pajamas suitable for warmer climates. Higher GSM values (220-300 GSM), conversely, produce thicker, warmer pajamas ideal for cooler weather. Manufacturers should consider regional preferences and intended use cases when selecting bamboo fabrics with appropriate GSM.

Industrial machinery used in bamboo fabric production often includes precision GSM measuring devices. These machines ensure consistency across batches of material and help control quality, especially when preparing fabric for custom printing.

Fabric Density and Its Impact on Custom Printing

While GSM represents the weight of the fabric, density refers to the compactness of the weave or knit. Bamboo fabrics are often created using jersey knit, interlock, or rib knit techniques, each with varying densities. The density of bamboo fabric impacts its ability to hold detailed custom prints.

High-density bamboo fabric provides a smooth surface that allows custom prints to be applied with precision, ensuring vibrant and lasting designs. On lower-density fabrics, print quality might suffer due to the presence of larger gaps between fibers. As a result, manufacturers must carefully assess the density profile of bamboo fabric before committing to custom printing processes.

Advanced industrial weaving machinery plays a major role in achieving desired density levels. Machines such as circular knitters or flatbed knitting machines are commonly used for bamboo fabric production. Calibration of these machines to create a uniform weave ensures optimal surface finish for printing applications.

Industrial Printing Machinery for Bamboo Pajamas

Once the fabric's GSM and density are determined, the focus shifts to printing technology. Custom print bamboo pajamas typically involve digital textile printers, screen printing techniques, or heat transfer systems to apply designs to fabric.

Digital Textile Printers

Digital textile printers are preferred for high-precision designs and smaller production runs. These printers use advanced nozzles to apply water-based inks onto the bamboo fabric, ensuring eco-friendly operations. Bamboo's inherent absorbent nature enables vibrant dye absorption, making it compatible with digital textile printing technology.

To accommodate the density and smoothness of bamboo fabric, digital printers are equipped with adjustable pressure plates and ink viscosity settings. Proper calibration ensures that intricate patterns and colors are accurately translated onto the fabric.

Screen Printing Techniques

Screen printing remains a popular choice for bulk production of custom print bamboo pajamas. This method involves creating stencils, known as screens, to apply ink through precise openings onto the fabric. Bamboo fabric’s stretchability and moisture-wicking properties necessitate high-quality screens and specialized inks to maintain consistency across designs.

Automated screen printing machinery significantly enhances efficiency in bulk production while ensuring uniformity across millions of pieces. , industrial washing systems integrated with these machines pre-treat the bamboo fabric before printing to prevent shrinkage or color bleeding during and after the process.

Heat Transfer Systems

Heat transfer technology is ideal for smaller designs or logos on bamboo pajamas. It involves transferring pre-printed designs onto the fabric using heat and pressure. This approach works exceptionally well on bamboo fabric with higher GSM, as its thickness ensures durability and protects against damage from heat exposure.

Industrial-grade heat transfer systems feature adjustable pressure and temperature settings to cater to variations in bamboo fabric GSM and density. Automated feeders ensure precision placement of designs, and rapid cooling mechanisms preserve fabric integrity post-transfer.

Sustainability Benefits of Bamboo Fabric

Beyond technical considerations, bamboo pajamas offer sustainability benefits that align with global demand for eco-friendly textiles. Bamboo is a fast-growing plant that requires minimal water and no chemical fertilizers or pesticides, making it an environmentally responsible choice. Additionally, the fiber is biodegradable, reducing its impact on landfills.

Technological advancements in bamboo fabric production have minimized water and energy consumption during manufacturing. Closed-loop systems in industrial machinery, such as those used for dyeing and washing, recapture water and chemicals for reuse, further minimizing the ecological footprint of bamboo pajamas.

These attributes make bamboo a preferred material for businesses seeking to emphasize sustainability in their product lines. Combined with custom printing technologies, bamboo pajamas can serve as a differentiator in competitive B2B markets.

Post-Production Considerations

After custom prints are applied to bamboo pajamas, post-production processes such as quality inspections, packaging, and shipping come into play.

| Fabric Type | Organic Bamboo |

| Compliance | GOTS Organic |

| Customization | Private Label |

| Lead Time | 31 Days |

Quality Inspections

Industrial-quality control machinery plays a crucial role in post-production. Fabric scanners identify inconsistencies in printing or weaving, while tensile strength test machines evaluate the durability of finished products. Maintaining stringent quality standards is essential for B2B transactions, where businesses rely on consistency to build trust with their clientele.

Packaging and Branding

Custom print bamboo pajamas often demand equally tailored packaging solutions. Automated folding and bagging machines streamline packaging for large production volumes. Integrating branding elements such as eco-friendly tags and labels made from recycled materials reinforces the sustainability narrative and enhances brand appeal.

Shipping and Distribution

The lightweight nature of bamboo fabric, especially in lower GSM ranges, reduces shipping costs. , advancements in logistics technology, such as pattern-based loading systems on shipping vehicles, optimize the distribution efficiency of bulk orders to B2B clients. This makes bamboo pajamas an attractive option not only for their quality but also for their cost-effectiveness in supply chain operations.

Custom print bamboo pajamas represent a harmonious blend of sustainability, technical innovation, and aesthetic appeal. From precise GSM calibration and density optimization to advanced industrial printing machinery, every step of the production process demands meticulous attention to detail. By leveraging cutting-edge technology and environmentally conscious practices, businesses can cater to a growing demand for personalized, eco-friendly sleepwear in the B2B sector. Bamboo pajamas, with their superior comfort and customizability, offer significant potential for differentiation in a crowded textile market.