lowest price knitted Baby Rompers One Piece Jumpsuit company

1

Lowest Price Knitted Baby Rompers One Piece Jumpsuit Company

When it comes to sourcing affordable and high-quality baby clothing, finding the right supplier is critical for B2B businesses in the apparel industry. Baby rompers, particularly knitted one-piece jumpsuits, are in demand due to their comfort, practicality, and durability. This article explores how this factory offers the lowest price options while maintaining superior quality standards to meet industry expectations.

The Competitive Edge of Our Facility

This factory specializes in producing knitted baby rompers and one-piece jumpsuits at unbeatable price points. The production process capitalizes on cost-efficient operational strategies, bulk raw material purchasing, and streamlined manufacturing techniques. By reducing wastage and optimizing every step from weaving to packaging, this facility ensures that its product pricing remains highly competitive without compromising on quality.

Material Sourcing for Knitted Baby Rompers

The commitment to quality begins with careful selection of materials. This factory prioritizes sourcing soft and breathable fabrics suitable for sensitive baby skin. Organic cotton, bamboo fiber, and other eco-friendly textiles are commonly utilized, ensuring comfort, sustainability, and longevity of the products. In fact, bamboo fabric has gained attention for its hypoallergenic features, making it a standout choice for baby clothing. This facility also integrates processes to create toy story bamboo pajamas, catering to licensed designs in larger-scale production.

Design and Variety in Baby Jumpsuits

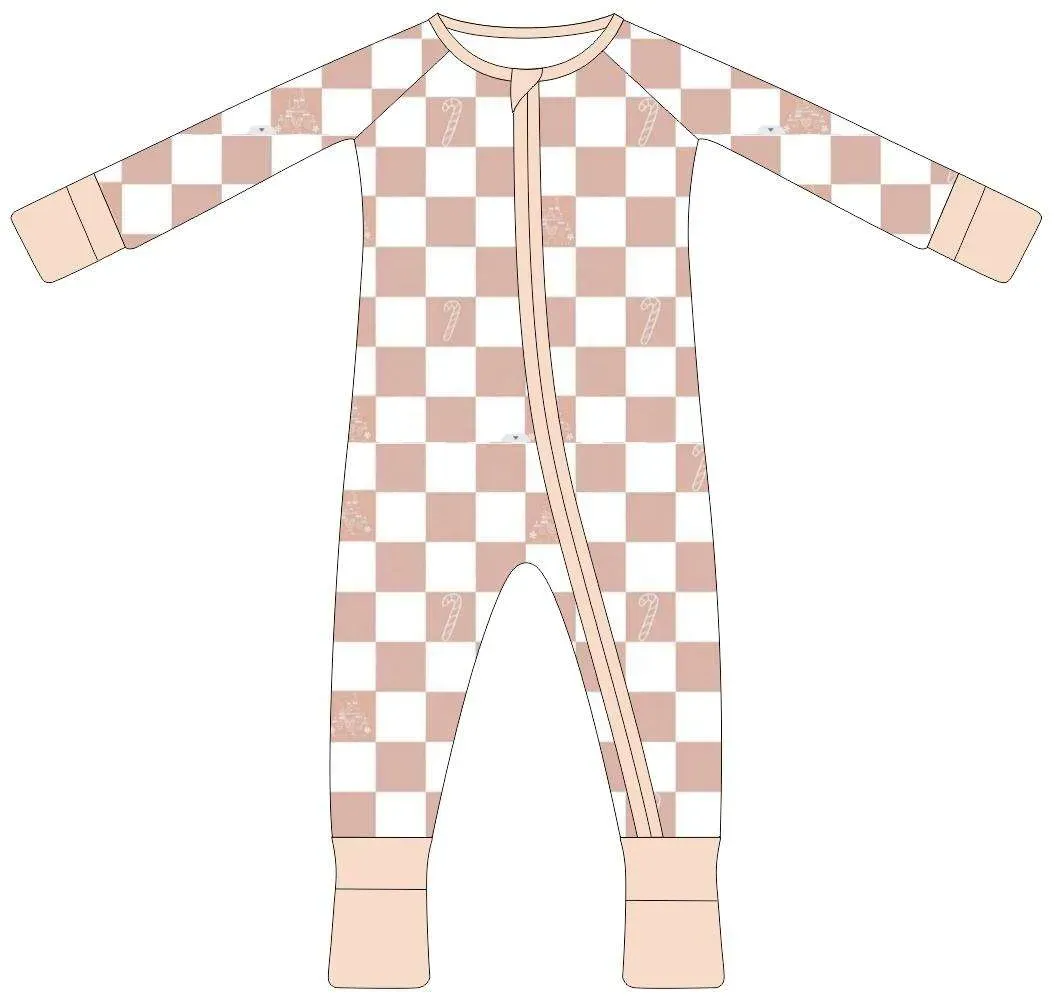

Understanding diverse market preferences is key to driving sales volume. This factory produces knitted baby rompers in a wide range of designs, colors, and sizes. From minimalist, pastel options to playful patterns with whimsical prints, the collection meets varied customer demands. The focus remains on providing functional designs with features such as envelope necklines for ease of wear, snap-button closures for quick diaper changes, and reinforced stitching for durability.

Custom Manufacturing Capabilities

For B2B partners seeking tailored solutions, this facility excels in custom manufacturing. Whether the requirement is specific branding, embroidery, or private labeling, the production department accommodates requests efficiently. Bulk orders of toy story bamboo pajamas, custom pyjamas for kids, or licensed thematic designs are handled seamlessly without inflating costs or compromising delivery schedules. This flexibility sets this factory apart as a reliable partner for long-term collaboration.

Cost Optimization of Knitted Baby Rompers

Producing at scale remains a critical factor in keeping overhead costs low. By leveraging automated knitting and sewing technologies, this facility delivers high-volume production without the expense typically associated with labor-intensive processes. The equipment used optimizes precision and consistency, ensuring minimal defects and reducing the need for quality control interventions.

Additionally, direct relationships with material suppliers allow the factory to secure bulk raw materials at reduced rates, passing cost savings directly to clients. Efficient logistics networks further reduce transportation expenses, ensuring affordable delivery even for international shipments. This supply chain integration maximizes cost control, making this factory a go-to source for affordable knitted baby rompers.

Eco-Friendly Practices in Manufacturing

Environmental considerations are central to the factory’s approach. Bamboo fiber, increasingly used for pajamas for women bamboo and infant clothing, plays a significant role in achieving sustainable production. Bamboo grows quickly and requires fewer resources than traditional textiles, making it an environmentally friendly choice. Production processes are designed to ensure minimal waste, and recycling mechanisms are actively employed to repurpose fabric scraps.

By adopting green practices, this factory meets client demands for ethical sourcing while setting an industry benchmark for sustainable apparel manufacturing. Buyers can market their products confidently as eco-friendly, enhancing their appeal to environmentally conscious consumers.

Quality Assurance Standards

Even with cost reductions, adherence to high-quality standards remains pivotal. Each knitted baby romper undergoes thorough inspection to meet durability, aesthetic, and comfort expectations. Parameters such as stitching strength, fabric softness, and shrinkage resistance are rigorously tested. High attention to detail ensures that even delicate embellishments or complex designs maintain integrity after multiple washes.

Compliance with international safety and quality guidelines is also guaranteed. Baby clothing must prioritize safety elements such as non-toxic dyes and absence of choking hazards. This factory complies with these regulations, reassuring clients about product reliability and market acceptance in stringent regions.

Fast and Reliable Distribution Channels

Timely delivery is essential for maintaining customer satisfaction, especially in fast-paced retail environments. The factory has developed a robust logistics framework to ensure efficient distribution. Orders for toy story bamboo pajamas, knitted baby rompers, and other specialized designs are fulfilled within tight deadlines, regardless of order sizes.

Additionally, clients can benefit from a transparent tracking system that provides real-time updates on shipping progress. Whether serving domestic retailers or global distributors, this factory ensures a consistent supply chain experience that enhances buyer confidence.

Scalability to Meet Growing Demands

Dynamic markets require a factory capable of scaling production to meet demand peaks. This facility is equipped to handle surges during peak seasons, such as back-to-school campaigns or holiday promotions. Automated technologies and modular production systems enable volume adjustments without hurting efficiency or quality metrics.

This scalability makes it possible for B2B buyers to plan ahead and capitalize on trends, such as thematic collections like pyjamas for kids or pajamas for women bamboo. By maintaining flexibility in manufacturing, the factory delivers high-value solutions for both small and large enterprises.

Collaborative B2B Partnership Benefits

Working directly with the factory brings significant advantages for businesses. Establishing long-term contracts often results in priority order handling, discounted pricing tiers, and access to exclusive designs. The factory’s production experts also provide valuable insights regarding market trends, helping clients optimize their inventory assortments and tap into growing niches like toy story bamboo pajamas collections.

, B2B clients benefit from streamlined communications and dedicated account managers who address concerns or expedite processes as required. This collaborative approach supports growth-oriented business strategies for buyers seeking consistent, cost-effective product sources.

Final Thoughts on Strategic Sourcing

This factory stands as a benchmark for affordable, high-quality knitted baby rompers and one-piece jumpsuits. By combining cost-efficient manufacturing, eco-friendly practices, custom production capabilities, and robust logistics frameworks, it ensures that B2B buyers receive products that match their competitive market demands. Leveraging this partnership can drive substantial value for businesses engaged in the children’s apparel sector or exploring themed niches like pajama collections for kids and women.