girls Footwear Jumpsuit OEM best quality

1

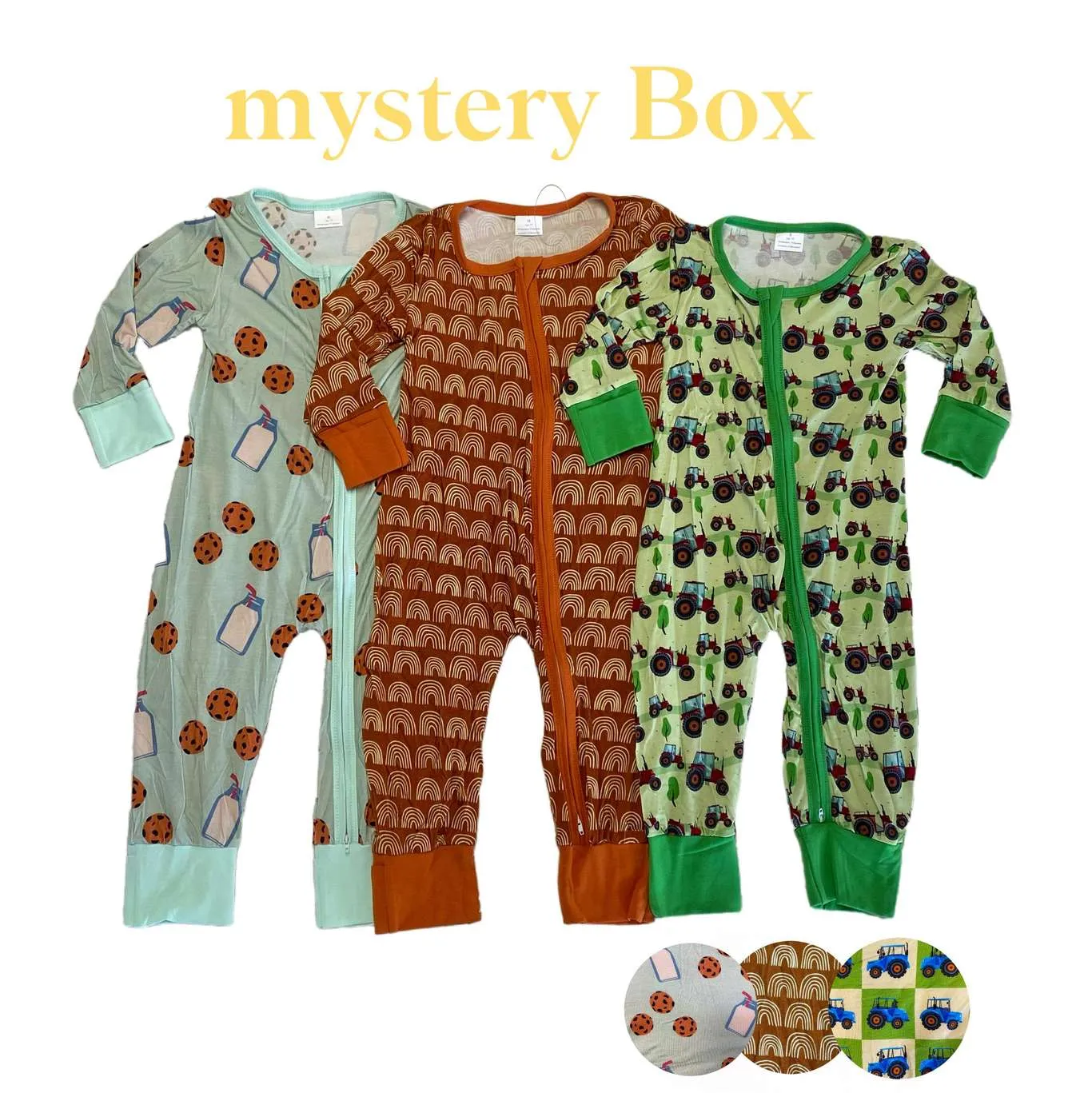

Girls Footwear Jumpsuit OEM: Delivering Top-Tier Quality at Scale

In the competitive world of apparel manufacturing, Original Equipment Manufacturer (OEM) facilities must excel at several levels when producing high-quality products like girls’ footwear jumpsuits. By focusing on innovative design, sustainable materials, and efficient processes, this factory ensures the delivery of premium products that meet the demands of B2B partners. Below, we explore how OEM partnerships can offer unparalleled quality within this niche while staying aligned with market demands for sustainability and functionality.

Material Selection: The Foundation of Quality

The choice of materials is a driving factor behind producing premium girls' footwear jumpsuits. This factory prioritizes sourcing fabrics and materials that combine durability, comfort, and aesthetic appeal. Particularly in today’s market, there is a growing focus on environmentally friendly options, which has led to a surge in the use of materials such as bamboo fiber. For instance, fabric technologies derived from bamboo, already popular in products like the bamboo onesie, are now being innovatively applied to jumpsuit designs.

Bamboo fabric offers several advantages: it is naturally soft, hypoallergenic, and moisture-wicking, making it an excellent choice for apparel intended for children. These characteristics help manufacturers deliver jumpsuits that meet the high expectations of both retailers and end consumers. Sustainability is seamlessly embedded without sacrificing functionality or comfort. By leveraging these materials, our facility ensures consistency in product quality while keeping pace with eco-conscious market trends.

Design Versatility Meets Functionality

The production of girls’ footwear jumpsuits requires a balance between style and practicality. Modern buyers prioritize garments that are easy to wear, durable, and stylish. To address this demand, our team works alongside buyers to customize designs that reflect their specific requirements.

For specialized designs intended for younger consumers, elements like reinforced stitching and soft linings are often incorporated into production. Features such as snaps or zippers for easy wearability are often demanded, mirroring successful trends in related products like a bow bamboo pajama or women pajamas bamboo. These touches ensure the jumpsuits remain durable and maintain an appealing aesthetic for discerning customers.

Prototyping is another crucial phase of the design process. Before scaling production, sample runs allow buyers to evaluate fabric compatibility, fit, and design intricacies. Advanced prototyping methods, combined with detailed client feedback, enable the factory to refine designs efficiently and meet expectations without unnecessary delays.

Emphasis on Sustainability in Manufacturing

Children's apparel, including footwear jumpsuits, finds increasing alignment with sustainable manufacturing practices. With concerns around waste and environmental impact growing, this factory integrates sustainability across the production chain. One of the key initiatives involves using biodegradable and recyclable materials, inspired by the success of natural fibers in other clothing segments—including bamboo-derived fabric applications in products like the bamboo onesie.

Additionally, investments in greener production methods have allowed us to reduce water usage while enhancing energy-efficiency measures throughout our facility. Incorporating ethical sourcing practices for raw materials ensures that end-products reflect not just quality but also a brand ethos suited to environmentally mindful consumers.

High-Precision Manufacturing for Superior Output

Scaling production without compromising quality requires robust in-house infrastructure. One of the hallmarks of this factory's commitment to quality is its use of advanced machinery that enables high precision in every aspect of manufacturing. For girls’ footwear jumpsuits, this means ensuring seams are flawless, fabric treatments are uniform, and printing or embroidery is consistent across large production batches.

Each production stage, from pattern cutting to final assembly, undergoes rigorous quality checks to catch potential defects. Automated systems offer time efficiencies without removing the human eye for detail—an element particularly essential when producing detailed garments for children.

Customization Options Tailored to Business Needs

OEM production thrives on flexibility, and this factory offers a wide range of customization options for clients. Whether it's selecting specific fabric blends, choosing fastener types, or even developing completely original designs, our emphasis is on meeting the precise specifications laid out by our business partners.

For example, businesses looking to expand their product lines beyond jumpsuits often coordinate projects that link complementary offerings such as bow bamboo pajamas or women pajamas bamboo. Such arrangements allow for cohesive consumer collections while leveraging economies of scale in production.

Adding value through customization ensures optimal satisfaction for both retailers and consumers. By addressing details as fine as thread colors or branding labels, this factory aids its clients in differentiating their products in highly competitive markets.

Scalability and Efficiency in Bulk Production

One of the key challenges OEM manufacturers face is achieving scalability without a dip in quality. Meeting seasonal demands or bulk orders for retail campaigns requires operational excellence. Our facility achieves this by employing lean manufacturing principles, which optimize workflows and minimize waste.

Real-time adjustments during production also play a vital role. For example, if a retailer requests slight design modifications partway through a run, the structure of the production line allows our teams to accommodate these needs with minimal disruption. Such capabilities are critical during peak sales seasons, ensuring delivery schedules remain consistent.

Strict Quality Assurance Protocols

Our quality assurance (QA) protocols are designed to guarantee end-products that surpass client expectations. QA teams assess physical durability, fabric integrity, stitching accuracy, and adherence to the original prototype specifications. Defect rates are maintained below industry standards to uphold a reputation for reliability and trustworthiness in our finished goods.

, testing processes for children’s apparel factor in safety standards and compliance. For instance, fasteners are tested for durability, while fabric is reviewed for hypoallergenic properties—mirroring the stringent criteria often seen in other clothing, such as women's pajamas bamboo-crafted items.

Packaging and Logistics: Completing the OEM Lifecycle

The importance of packaging cannot be overlooked when it comes to apparel manufacturing. This factory offers various customizable packaging solutions, designed to enhance product presentation upon delivery. Retailers can opt for branded, eco-conscious packaging that aligns with their identity, making the unboxing experience a key selling point for buyers.

Logistics are streamlined through advanced tracking systems and partnerships with reliable shipping providers, ensuring timely delivery regardless of order volumes or destination. From smaller trial orders to full-scale retail shipment, clients can rely on seamless coordination to maintain supply chain efficiency.

Capturing Market Trends with Adaptability

The dynamic nature of the children's apparel segment demands a manufacturing approach that is both proactive and adaptive. By staying informed on market shifts—such as the increasing preference for bamboo-based products, evident in categories like the bamboo onesie or bow bamboo pajama—this factory positions itself as a trusted partner for B2B clients.

The ability to innovate quickly based on evolving fashion trends keeps our product catalogs relevant and appealing. For girls’ footwear jumpsuits, we have anticipated the blending of bold patterns, pastel tones, and multi-functional designs that parents increasingly seek.

Conclusion: Seamlessly Meeting OEM Demands

This factory places a premium on delivering quality girls’ footwear jumpsuits by building strong partnerships with clients, leveraging sustainable materials, and ensuring precision-focused manufacturing. The commitment to innovative designs, bulk scalability, and ethical practices positions us as a key player in the OEM apparel industry.