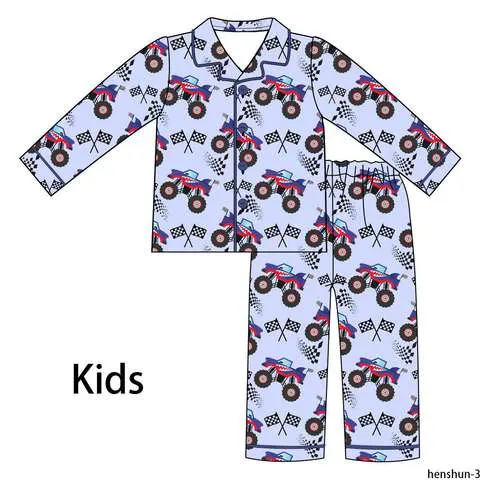

Bespoke Plain Bamboo Pajamas Family Oem Exporter

Engineering Comfort: The Science Behind Plain Bamboo Pajamas for Families

As demands for eco-friendly textiles rise, bamboo fabrics have carved a niche in the fabric industry for their sustainability, comfort, and versatility. Among these, plain bamboo pajamas tailored for families stand out as a durable and sustainable option. In this article, we’ll delve into the critical parameters of fabric engineering—GSM (grams per square meter), fabric density, and the industrial machinery utilized to produce these products. Below, you’ll find an in-depth analysis of the technological aspects of creating bamboo pajamas engineered to meet market demands.

The Role of GSM and Fabric Density in Bamboo Pajamas

Grams per square meter (GSM) is a foundational aspect in fabric selection and manufacturing. For bamboo pajamas, which require a balance of breathability, softness, and durability, GSM plays a pivotal role in determining the weight and feel of the garment. Ideally, pajamas should sit in the range of 150 to 220 GSM, as this range offers an optimal level of lightweight wearability while preserving durability.

Fabric density is another critical parameter. Unlike GSM, which measures fabric weight, fabric density defines the tightness of the fabric weave or knit. For bamboo fabric, a high-density weave ensures better durability and resistance to pilling, which is particularly critical for family pajamas designed to undergo frequent washing and wear. Achieving the correct balance between GSM and density enhances not only the comfort but also the lifespan of the fabric.

Why Bamboo Fiber Excels in Pajama Fabric

From an engineering standpoint, bamboo fiber offers distinct advantages over traditional cotton and synthetic options. It has a unique cellular composition that grants it superior moisture-wicking properties and breathability. This makes it particularly suitable for pajamas, which are often in direct contact with skin for extended periods.

Bamboo pajamas also naturally inhibit the growth of bacteria, thanks to the inherent properties of bamboo fibers. This reduces odor retention, which is vital for garments worn frequently. , bamboo fibers are softer to the touch compared to their cotton counterparts because they can be processed into viscose or lyocell, both of which result in fabrics with high tensile strength and flexibility. This makes them ideal for family pajamas, where comfort is at the forefront of design considerations.

Industrial Machinery for Bamboo Pajama Production

The production of plain bamboo pajamas relies on state-of-the-art industrial machinery that ensures precision and scalability. Let’s take a closer look at some of the crucial machines and their roles in the manufacturing process:

Fiber Extraction and Processing Machines

The manufacturing journey begins with the extraction of bamboo fibers. The "mechanical retting" process uses shredding machines to break down bamboo into raw fibers. These fibers are then treated with natural enzymes to soften them further. Technological advancements in enzymatic retting machines have allowed manufacturers to optimize this process for higher yield and reduced environmental impact.

Knitting and Weaving Machines

The engineering focus shifts to knitting and weaving machines during the fabric-making stage. For bamboo pajamas, circular knitting machines are often preferred because they produce a seamless, stretchable fabric ideal for loungewear. High-speed knitting machines equipped with automatic controls ensure that fabric density and elasticity are consistent across batches.

Alternatively, for plain-woven bamboo fabrics, advanced air-jet looms are utilized. These machines use compressed air to insert the weft, ensuring that the weaving process is both fast and accurate. The result is a uniform, high-density fabric that forms the base for durable pajamas.

Dyeing and Finishing Machines

Color and texture finishing are critical in achieving the aesthetics and tactile qualities expected from family pajamas. Dyeing bamboo-based fabrics involves using low-impact dyes, a key in preserving the eco-friendly credentials of bamboo textiles. Special dyeing machines ensure uniform color absorption.

| Fabric Type | Pima Cotton |

| Compliance | OEKO-TEX 100 |

| Customization | OEM |

| Lead Time | 39 Days |

After dyeing, finishing machines equipped with calendaring rolls are used to smooth and soften the fabric. This step is essential for adding the extra touch of luxury that family pajamas often demand. Steam sanforizing equipment is also employed to stabilize the fabric and minimize shrinkage during repeated washes.

Cutting and Sewing Machines

Once the fabric is ready, precision cutting machines powered by computer-aided design (CAD) technology ensure minimal wastage and maximum efficiency. For family pajamas, patterns are typically graded into various sizes to accommodate all age groups, from toddlers to adults.

Finally, industrial sewing machines stitch the pieces together, often equipped with advanced stitching technologies such as flatlock seams to enhance durability and comfort. Sewing machine automation ensures consistency across all products, which is vital in B2B transactions where bulk orders demand uniformity.

Quality Control and Product Lifecycle

At every stage of manufacturing, rigorous quality control processes are essential. Bamboo pajamas undergo multiple rounds of testing to ensure the fabric lives up to industry standards in terms of GSM, tensile strength, and dimensional stability. Random fabric sampling and stress tests ensure that the products maintain their form and integrity even after extended use.

, the life cycle of bamboo pajamas is often extended through proper product care instructions provided to the end consumer. Detailed washing guidelines, often on garment labels, help maintain the softness, shape, and durability of these family-friendly products.

The production of plain bamboo pajamas for families demonstrates the intersection of sustainability, comfort, and cutting-edge industrial processes. From selecting the ideal GSM and fabric density to leveraging advanced weaving and finishing machinery, every step is finely tuned to meet the demands of comfort and quality. For businesses seeking to differentiate their textile offerings in a green-conscious market, plain bamboo pajamas provide a compelling product option. As industrial machinery continues to evolve, the scope for innovations in bamboo textiles only grows, ensuring that family comfort meets sustainability in new, exciting ways.