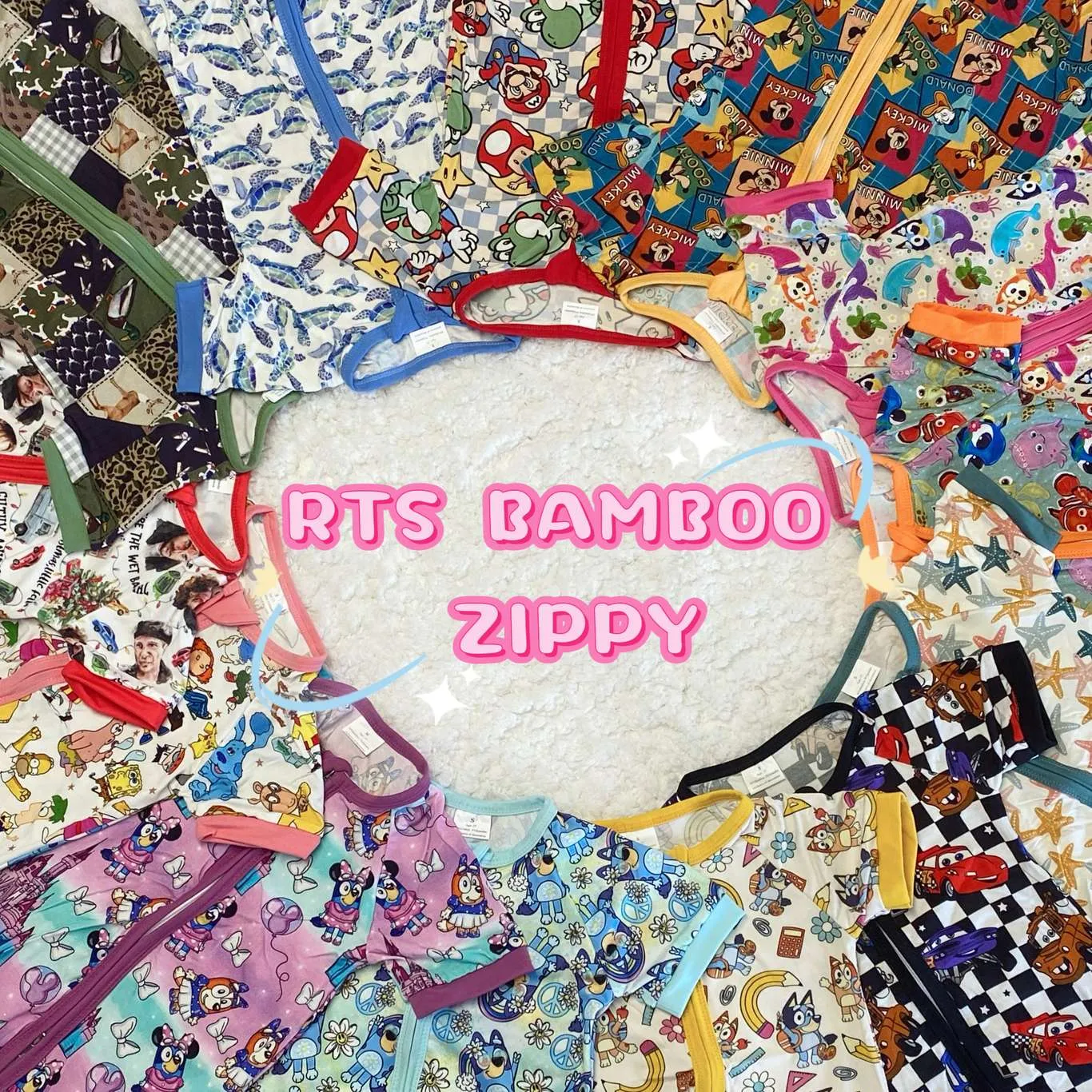

bamboo postpartum pajama set

1

Bamboo Postpartum Pajama Set: A Technical Perspective for Boutique Owners

As boutique owners venture into sourcing bamboo postpartum pajama sets, pinpointing the technical details is vital for ensuring product quality and meeting customer demands. Bamboo fabric has become a sought-after choice for postpartum apparel due to its inherent features, including breathability, moisture-wicking capabilities, and sustainable sourcing. But to truly understand its place in the market, we must dissect the elements that make bamboo fabric exceptional and focus on pain points within manufacturing and procurement. This blog post will serve as a deep technical exploration for B2B stakeholders.

The Fabric Foundation: Bamboo Yarn and Knitting Techniques

At the heart of bamboo postpartum pajama sets lies the bamboo yarn itself, which is derived from bamboo pulp through chemically or mechanically processed viscose methods. For postpartum wear, optimal softness and stretch are essential to ensure comfort for women recovering from childbirth. This is achieved by leveraging knitting methodologies such as single jersey or rib knitting, which provide a balance of softness and elasticity. Rib knitting, for example, uses finer bamboo yarn with a count often between 30s and 40s to ensure lightweight and flexible fabrics while retaining durability. Boutique owners looking for pajama sets with added stretch should factor in knitting specifics during procurement.

Fabric Weight and GSM Considerations

GSM (grams per square meter) directly correlates to the thickness and weight of bamboo fabric. A range of 180-220 GSM is ideal for postpartum pajamas. Fabrics below 180 GSM tend to be too thin, potentially reducing durability over time, while weights above 220 GSM may compromise breathability, leaving the wearer uncomfortable. This range ensures that the fabric achieves the perfect balance of smoothness and structure while remaining suitable for year-round wear. It's recommended to request GSM testing reports from suppliers, especially for postpartum pajamas marketed under the "bamboo lab h2d" branding, where consistency in GSM numbers is crucial to secure customer satisfaction.

Enhanced Stitching Density and Seam Comfort

Bamboo postpartum pajama sets require stitching refinement for both aesthetics and practicality. Stitching density, measured in SPI (stitches per inch), impacts the durability and product appeal. Pajamas stitched with SPI between 8 and 12 are more resistant to daily wear, ensuring fewer instances of seam bursting. For pajamas specifically designed for postpartum recovery, the seams should feature lock-stitch techniques combined with overlocked edges to prevent fraying and irritation. Seamless constructed apparel, common in bamboo fabric manufacturing, can also address skin-sensitive clientele particularly susceptible to irritation during postpartum recovery.

Industry Pain Points and How They Relate to Bamboo Apparel

B2B procurement of bamboo postpartum pajama sets often sees challenges related to scalability, environmental certifications, and delivery timelines. These three factors play a critical role in boutique purchasing decisions:

Scalability and Customization Challenges

One pressing pain point in manufacturing bamboo apparel is scalability. For boutique owners handling smaller orders, balancing customization requests with manufacturing MOQs (minimum order quantities) can become difficult. For example, requests for specific GSM fabrics, specialized prints such as "custom Printed Bamboo Newborn Girls' Print Roupa Infant Infantil Jumpsuit Romper Babyclothes," or unique sizing require efficient communication with suppliers. Manufacturers offering "bamboo lab h2d" processes are best at scaling these requests without compromising the quality of the final garment. Ensure that your manufacturers use CAD (Computer-Aided Design) templates for seamless transition between designs and bulk production while maintaining accuracy.

Certifications for Eco-Friendly Appeal

Bamboo’s sustainability claims attract environmentally conscious consumers, making certifications such as OEKO-TEX Standard 100, GOTS (Global Organic Textile Standard), and USDA Organic Certification critical for boutique credibility. A vendor selling bamboo pajamas without these certifications risks alienating eco-conscious buyers. Bamboo apparel manufacturers using closed-loop processing systems—which capture and recycle solvents—are preferable from both sustainability and ethical standpoints. These standards build trust and reinforce the product’s premium positioning in boutique retail environments.

Delivery Timelines and Efficient Vendor Communication

In B2B sourcing, timing is everything. Postpartum apparel buyers often face challenges when they rely on manufacturers that fail to provide detailed lead time estimates. Bamboo viscose production involves multi-stage processing, making communication around timelines essential. Ideally, build relationships with vendors who can provide consistent updates on stock availability and potential disruptions. It's particularly important when procuring pajama sets tied to seasonal promotions or custom Printed Bamboo Newborn girls’ designs—delays could result in missed revenue opportunities.

How Printing Specifications Affect Bamboo Pajama Quality

Print design is often overlooked when sourcing postpartum pajama sets, but it plays a vital role in meeting consumer expectations. Bamboo fabric's smooth surface offers compatibility with techniques such as reactive dye printing or pigment printing. For boutique owners collaborating on custom designs like those seen in Printed Bamboo Newborn Girls' Print Roupa Infant Infantil Jumpsuit Romper Babyclothes, it’s crucial to assess the printing durability hardware the manufacturers use. For example, reactive dye printing integrates color directly into bamboo fibers, ensuring fade-resistance but requires thorough washing to remove excess dye. This process suits postpartum pajamas with intricate motifs requiring vibrancy even after prolonged usage.

Balancing Aesthetic and Functional Needs

The appeal of bamboo postpartum pajama sets also lies heavily in the functional design from cut patterns to embellishments. Practical features such as nursing accessibility via snap buttons, zipper additions, or overlapping fronts make the sets more appealing and marketable. During procurement, boutique owners can suggest features like stretch-enhanced waistbands and moisture-wicking panels to address postpartum physiological changes, ensuring the pajama sets aid recovery while maintaining style.

Additional customization options include heat-transferred tags or tag-less designs to improve wearer comfort further. Combining this with bamboo’s natural thermoregulation ensures maximum usage across climates. As boutique owners look for vendors offering bespoke services, it’s critical to request detailed samples showcasing both aesthetic and functional elements during discussions.

Final Thoughts on Maximizing Procurement Efficiency

Ultimately, sourcing bamboo postpartum pajama sets requires a deep understanding of both manufacturing intricacies and market positioning. As you navigate vendor relationships, focus on those that provide detailed fabric specifications—especially around GSM weights, SPI density, and eco-certifications. For boutique owners catering to postpartum recovery needs, these technical details allow for better differentiation, higher repeat customer rates, and alignment with the trend toward natural fibers. Bamboo lab h2d processes promise reliable fabric refining, making them an ideal partner for producing high-quality pajama sets. Combine industry-specific knowledge with practical printing collaborations like those seen in "custom Printed Bamboo Newborn Girls' Print Roupa Infant Infantil Jumpsuit Romper Babyclothes" offerings, and boutique owners can ensure a steady growth trajectory within the lucrative postpartum niche.